Empower your life.

Quickly Responding to Infectious Diseases and Contributing to Stakeholders

Mask production began as a volunteer activity.

Since January 2020, COVID19 has been raging around the world. As preventive measures began in many countries, masks were the center of attention. Demand for them surged worldwide, and Japan began to experience shortages around the beginning of February. In addition to the shortage of masks from overseas, the rampant buying up of them on the Internet for resale spurred the shortage, perpetuating the lack of masks. In response, Brother began mask production and focused on activities that protect employees and their families while also contributing to society.

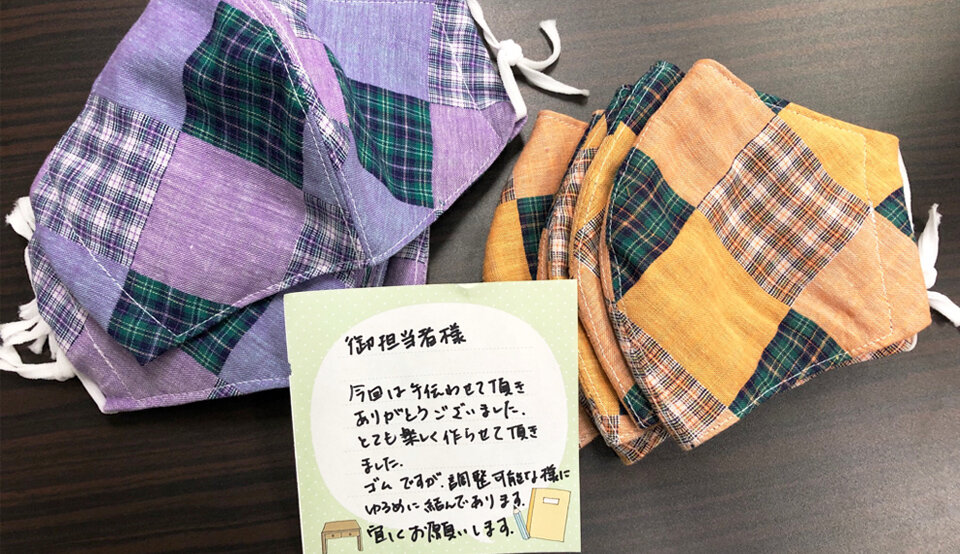

A circle of in-house volunteer activities to protect employees

In response to the spread of COVID19, Brother has encouraged the employees to work from home, but specific jobs, such as technical development and production line work, coming to work is unavoidable. Therefore, it became mandatory to wear masks as a measure to prevent infection in the company. However, they were still in short supply in the market. The president of Brother, who is also a member of sewing machine manufacturers, voiced the idea of making masks ourselves. At that time, double gauze, a common material for cloth masks, was already in short supply. Brother managed to procure the fabric and examined the shape of masks to produce them in greater quantities using limited materials. Brother cut out enough material for about 2,700 masks in total and asked for volunteers to sew them on the company intranet site. Many Brother group employees and their families joined in. After the masks were sewn by volunteers, they were displayed in the company with attached messages and all the masks were taken home by the end of the day.

Started production of non-woven masks

Cloth mask supplies by volunteers helped employees who were unable to obtain masks at the time, but there was a limit on production capacity. As more employees needed masks, we began setting up a production line for non-woven masks by utilizing Brother's manufacturing know-how. Through a network of affiliated companies, Brother acquired out-of-use used production equipment, and formed a cross-company team of production engineers and quality control departments to achieve quick operation within a month and a half. Mask production was a new experience for Brother, but it was up and running despite the various difficulties encountered. In June, Brother donated 50,000 masks to Nagoya City and 10,000 to Kariya City, and both cities distributed them to welfare facilities. The facilities that received the masks said that the mask quality was excellent and that they would like to pay for the masks next time. We have also started to sell the masks to our employees and business partners.

The movement to support mask production around the world

There have been movements regarding masks not only in Japan but also in the Brother Group around the world. Brother International Corporation (U.S.A.), our group company, donated 100 industrial sewing machines to four apparel companies for the production of personal protective equipment including masks.

SDGs goal 3 calls for “good health and well-being,” while “ensuring healthy lives and promote well-being for all at all ages” including target 3.3 which aims to "combat communicable diseases" Brother aims to realize the SDGs through the production of non-woven masks, and will continue to make social contributions in the future.

Share this article on social media

Learn about this initiative's SDGs

In ”SDGs at a Glance,” the 17 goals of the SDGs are explained in easy-to-understand illustrations. Click on the goal you are interested in, and you can read about it in under a minute. Let's take a look at the SDG goals featured in this article.

Related Topics