Hear your ideas.

Environmental Performance of Printers Changed by Airflow

Printing business airflow simulation

To use electricity, we need to generate power. Renewable energy sources such as solar and wind power have increased in recent years, but most electricity is generated by thermal power using oil, coal, and natural gas. Therefore, the use of electricity creates carbon dioxide (CO2) emissions, which lead to global warming. Brother is developing power-saving technologies for printers to reduce CO2 emissions to deliver eco-friendly products.

Heat exhaust problems with laser printers

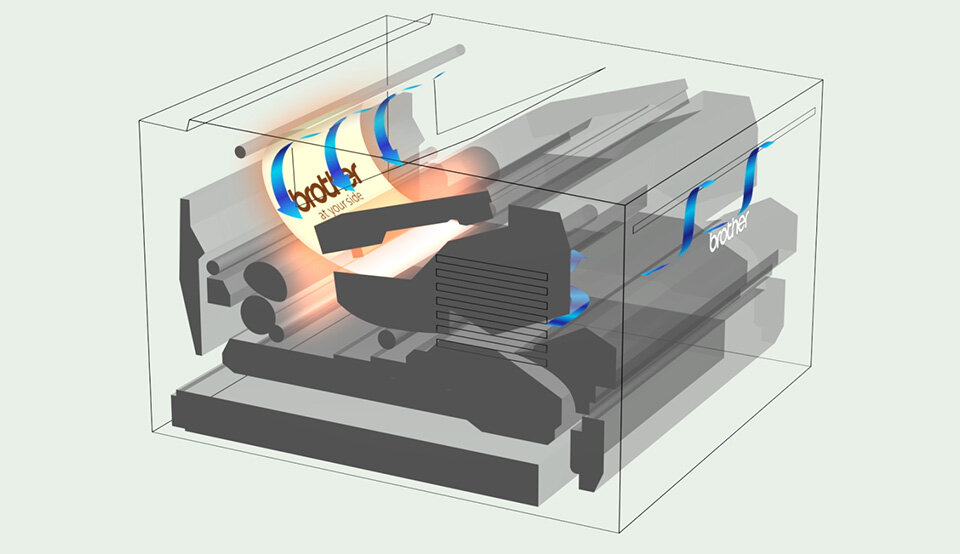

Laser printers use heat to fix colored powder called toner to paper, which generates high internal heat during printing. High heat can reduce the lifespan and electronic component durability and prevent the product from operating reliably. It is therefore necessary to vent the heat generated inside the printer to the outside (heat exhaustion) to achieve an appropriate internal temperature. Typically, cooling fans are used for heat exhaustion in electronic devices. However, since cooling fans consume electricity, environmental performance can be improved by reducing operating time or eliminating the cooling fan itself to create a fanless configuration.

Giving shape to contradictory ideals

If we increase a printer's printing speed to improve its performance, the temperature inside the device will rise. If we increase the number of parts for greater functionality and keep the casing compact, there is no room for heat to escape from the inside. While improving functionality and performance for the benefit of customers, we must also keep the inside of the product at an appropriate temperature. How can we achieve this contradictory ideal? Brother focused on the airflow through the narrow gaps inside the product and aimed to improve durability and energy-saving performance by controlling airflow appropriately.

Predicting airflow for both high functionality and environmental performance

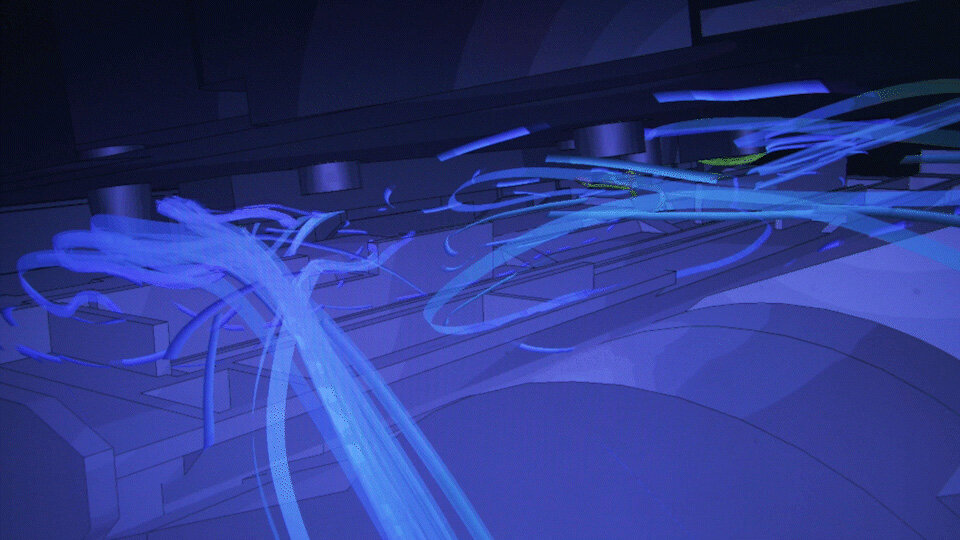

Previously, airflow measurement was done while running a prototype, which required a long time to grasp the full picture. Additionally, adjustments required advanced design techniques, it was a world of craftsmanship that relied on experience. With the introduction of the latest simulation technology, it is now possible to predict airflow at the design stage.

After a process of trial and error with both simulations and actual products, we were able to achieve an ideal airflow that improves thermal efficiency, which in turn improves energy-saving performance and increases the durability of the components in the product, contributing to longer service life. Furthermore, by reducing the number of cooling fans in some models, we were able to further reduce power consumption, leading to a highly functional, compact, and eco-friendly printer.

Air Flow Simulation Technology

SDGs goal 13 "Climate Action" calls for "taking urgent action to combat climate change and its impacts." By lowering the power consumption of its products, Brother contributes to alleviating climate change by reducing the generation of large amounts of CO2 emissions which has a significant impact on global warming.

Share this article on social media

Learn about this initiative's SDGs

In ”SDGs at a Glance,” the 17 goals of the SDGs are explained in easy-to-understand illustrations. Click on the goal you are interested in, and you can read about it in under a minute. Let's take a look at the SDG goals featured in this article.

Related Topics